Source: bing.com

Source: bing.comRubber pad is a type of rubber product that is commonly used in a variety of applications. It is made from natural or synthetic rubber and is designed to provide a cushioning effect, as well as protection from shock and vibration. Rubber pads are used in a range of industries, including automotive, construction, and aerospace. In this article, we will discuss the different types of rubber pads, their uses, and how they are manufactured.

Types of Rubber Pads

Source: bing.com

Source: bing.comThere are several types of rubber pads available in the market. Some of the most common types are:

Anti-Fatigue Mats

Source: bing.com

Source: bing.comAnti-fatigue mats are specifically designed to provide comfort and support to people who stand for long periods of time. They are used in commercial and industrial settings, such as in factories, warehouses, and assembly lines.

Rubber Shock Absorbers

Source: bing.com

Source: bing.comRubber shock absorbers are used to absorb shock and vibration in machines and equipment. They are commonly used in the automotive industry, as well as in construction and mining equipment.

Rubber Pads for Furniture

Source: bing.com

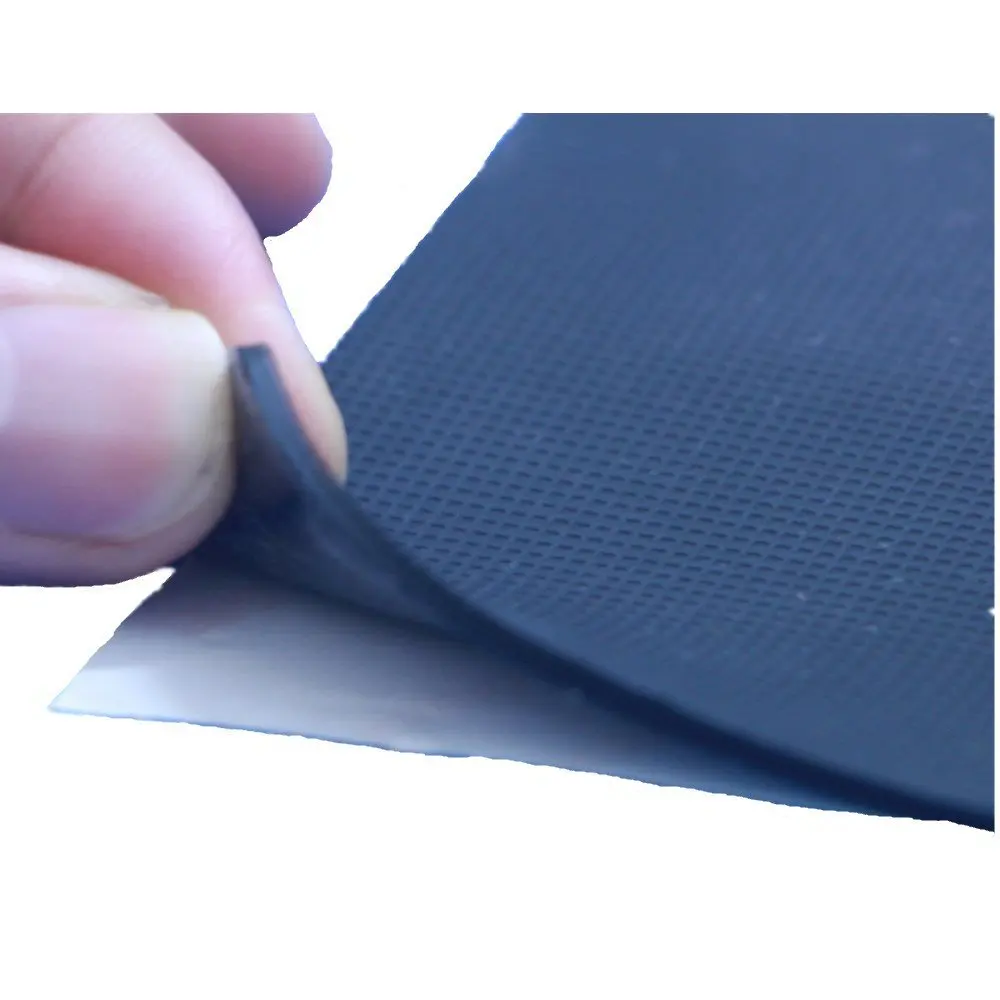

Source: bing.comRubber pads for furniture are used to prevent scratches and damage to floors. They are commonly used on chair legs, table legs, and other furniture items that can scratch floors.

Rubber Gaskets

Source: bing.com

Source: bing.comRubber gaskets are used to create a seal between two surfaces. They are commonly used in the automotive industry, as well as in plumbing and HVAC systems.

Manufacturing Process

Source: bing.com

Source: bing.comThe manufacturing process for rubber pads varies depending on the type of pad being produced. However, in general, the process involves the following steps:

Step 1: Mixing

The first step in the manufacturing process is mixing the rubber compounds. This involves blending different types of rubber, as well as adding other materials such as fillers, pigments, and additives.

Step 2: Molding

Source: bing.com

Source: bing.comThe rubber compound is then shaped into the desired form using a molding process. The molds are typically made from steel or aluminum and are designed to create the specific shape and size of the rubber pad.

Step 3: Vulcanization

Source: bing.com

Source: bing.comThe molded rubber pad is then heated in a vulcanization oven. This process involves heating the rubber at high temperatures and applying pressure to make it more durable and flexible.

Uses of Rubber Pads

Source: bing.com

Source: bing.comRubber pads are used in a variety of applications due to their cushioning effect and shock-absorbing properties. Some of the most common uses of rubber pads are:

Industrial Applications

Source: bing.com

Source: bing.comRubber pads are commonly used in industrial applications to provide cushioning and protection from shock and vibration. They are used in machinery, equipment, and even flooring to reduce the impact of heavy loads and vibrations.

Automotive Industry

Source: bing.com

Source: bing.comRubber pads are also used extensively in the automotive industry. They are used as shock absorbers in suspension systems, as well as in brake systems and engine mounts.

Furniture

Source: bing.com

Source: bing.comRubber pads for furniture are used to prevent damage to floors and to provide stability to chairs and other furniture items. They are also used as anti-skid pads for rugs and mats.

Conclusion

Rubber pads are versatile and useful products that are used in a variety of applications. They are made from natural or synthetic rubber and are designed to provide cushioning and protection from shock and vibration. The manufacturing process for rubber pads involves mixing, molding, and vulcanization. Rubber pads are used in industries such as automotive, construction, and aerospace, as well as in furniture and flooring. With their many uses and benefits, rubber pads are an essential component in countless products and applications.